Dokumentation

Ose_directory e-shot

2640 Visninger •Checkline II maintenance manual

3008 Visninger •Chemsplash Pro WD40 Test

2368 Visninger •Ergonomi 2006

2907 Visninger •Ose_directory Suspension harness

2678 Visninger •Procurement Guide annonce Health and Safety International - Europe's magazine for employee protection and personal protective equipment

3373 Visninger •Demonstration af velcro strop til montering/påsætning af gasdetektor på faldsikringssele

3145 Visninger •VISOR Installation steps

3933 Visninger •Desinfektionsprodukter med effekt på Coronavirus 2019-nCoV

2921 Visninger •Hearing protection 3M

2479 Visninger •Statistik for arbejdsmiljø 2014

2931 Visninger •LOTO_GuideBook_Europe_English

2482 Visninger •Remote area lighting system

2252 Visninger •Isol8 - The Ultimate Absorbent for Spills

2265 Visninger •Magazine Arbejdsmiljø - november 2012

2430 Visninger •KEE_DOME_MINI

2332 Visninger •TDS Speedglas 9100

2522 Visninger •The Pocketbook of Lean Visuals

2517 Visninger •Instructional video Sign holder

1809 Visninger •PREMARK installation manual

2471 Visninger •D-S CSR Håndbog

16770 Visninger •Find handskestørrelse - størrelsesguide for handsker

9852 Visninger •3M jupiter manual

6018 Visninger •9100 Manual

4884 Visninger •EN 388 nye mærkninger forklaring

4667 Visninger •D-S 70 års om os brochure

4622 Visninger •Forklaring af den nye EN ISO 374 kemikalier norm

4564 Visninger •Faldsikring flyer

4083 Visninger •Hvordan du kalibrere en 3M Jupiter luftstrøms enhed

3948 Visninger •VISOR Installation steps

3933 Visninger •Guide til valg af åndedrætsværn

3481 Visninger •TR-300 Bruger manual

3464 Visninger •VARMEX 2000 Fordele

3420 Visninger •Procurement Guide annonce Health and Safety International - Europe's magazine for employee protection and personal protective equipment

3373 Visninger •3M TR 300 PAPR training video

3322 Visninger •Demonstration af velcro strop til montering/påsætning af gasdetektor på faldsikringssele

3145 Visninger •Procedure for iklædning af engangsbeklædning

3122 Visninger •3020 Solcreme SPF 30 datablad

3105 Visninger •3M 8825+ 8835+ 06936+ 1895V+ BSI CE-Cert_(CE_705688_(Iss_30_09_2019))

3095 Visninger •Aura_Gen_3_BSI_Cert_(CE_681745_(Iss_07_10_2019)

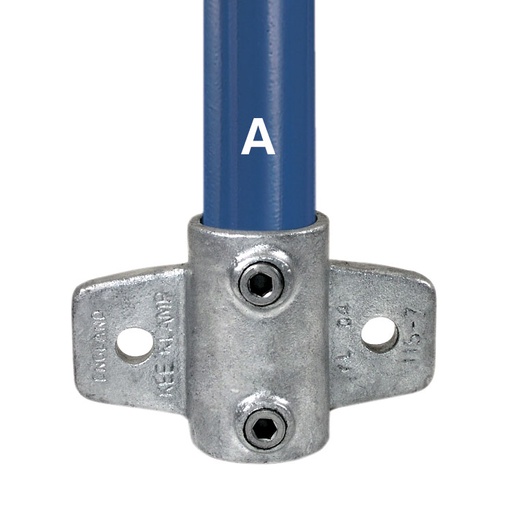

3059 Visninger •KEECompCat 52pp low res V2

| Visninger | |

|---|---|

| 758 | Totale visninger |

| 0 | Medlemmer visninger |

| 758 | Offentlige visninger |

Del via email

Venligst login for at dele dette document via email.

Indlejr på din hjemmeside

3. Copyright © Kee Safety Ltd. All Rights Reserved. www.keesafety.com 3 Contents t echnical Information 04 Kee K L a MP Components 06 Kee L I te Components 23 Kee aCC e SS Components 31 a ccessories 36 Safety Barrier Systems 37 Meeting Safety Standards 39 a ssembly and Installation 40 Load t ables 47 Vibration t est 50 K ee PROJ e C t S 51 Copyright © Kee Safety Ltd. All Rights Reserved. No part of this publication may be reproduced in any form without prior written permission from Kee Safety Ltd

52. Kee Safety Ltd 1 Boulton Road Reading R g 2 0N h United Kingdom Tel: +44 (0) 118 931 1022 Fax: +44 (0) 118 931 1146 Email: sales@keesafety.com www.keesafety.com K EE K LAMP , K EE L ITE , K EE A CCESS , KEE KOAT, KEE CHECK and K EE P ROJECTS are all registered trademarks of Kee Safety Ltd. w hilst every effort has been made to ensure the accuracy of the information contained in this brochure, Kee Safety Ltd cannot be held responsible for any errors or omissions. Kee Safety Ltd reserves the right to alter or withdraw products without prior notice. Kee Safety Ltd accepts no responsibility for any loss or damage arising from improper use of its products. Copyright © 2008 Kee Safety Ltd. All Rights Reserved. KS/COMPCAT_uk_v2/06_09

1. Safety Components Catalogue • FLEXIBLE SOLUTIONS FOR ALL TYPES OF SAFETY BARRIERS AND STRUCTURES • NO w ELDIN g OR T h READIN g • h I gh CORROSION RESISTANCE • w IDEST PRODUCT RAN g E AVAILABLE P ROVIDIN g SAFETY SOLUTIONS w ORL Dw IDE

38. Safety Components Catalogue 38 Copyright © Kee Safety Ltd. All Rights Reserved. L e V e L In Line Construction R a MPS S ta IRS P e D e S t RI a N GU a RDR a ILING The universal guardrailing solution. 10 21 15 20 25 26 67 86 87 88 89 Unique 0° to 11° range for in-line construction. Non-handed fittings allow consistent alignment of grubscrews. Maximum strength. Minimum installation time and cost. 27 29 28 30 90 92 91 93 Complies with BS 7818 Clause 2.4. Each railing is individually replaceable offering large cost savings when repair is necessary. 55 56

48. Safety Components Catalogue 48 Copyright © Kee Safety Ltd. All Rights Reserved. Span (m) Fitting Size 6 7 8 9 Tube Size (mm) 25 N.B. 32 N.B. 40 N.B. 50 N.B. Grade of Material – 6082 T6 Aluminium 0.3 1140 2468 4230 8693 0.6 285 617 1057 2173 0.9 126 274 470 965 1.1 84 183 314 646 1.2 71 154 264 543 1.5 45 98 169 347 1.7 35 76 131 270 2.1 23 50 86 177 2.3 - 42 71 147 2.4 - 38 66 135 2.7 - - 52 107 3.0 - - 42 86 Table 24: Beam load table (Kg) Values shown have a safety factor of 2 built into them and are based on the limit state of the material used. The values in Table 24 are an indication of a UDL that a rack consisting of two continuous support tubes can support. For uneven load distributions, the required tube size must be determined by standard bending moment and deflection calculations assuming the K ee LI te joint to give a simply supported beam. At loads greater than 770Kg* consi deration must be given to grubscrew slippage. (*A safety factor of 2 being applied in this instance.) a luminium Racking Load t ables Load (Kg) Table 23: Load tables (Kg) – fixed uprights Length (m) Fitting Size 5 6 7 8 9 Fitting Size 26.9mm x 2.6 33.7mm x 3.2 42.4mm x 3.2 48.3mm x 3.2 60.3mm x 3.6 0.3 1860 3086 4192 4916 7250 0.4 1600 2810 3910 4638 6930 0.5 1360 2534 3628 4360 6610 0.6 1140 2258 3346 4082 6290 0.7 940 1982 3064 3804 5970 0.8 775 1706 2782 3526 5650 0.9 640 1471 2500 3384 5330 1.0 540 1269 2235 3248 5010 1.1 - 1092 1995 2970 4690 1.2 - 937 1779 2692 4370 1.3 - - 1587 2414 4050 1.4 - - 1417 2169 3730 1.5 - - 1265 1954 3410 1.6 - - 1130 1764 3130 1.7 - - - 1602 2890 1.8 - - - 1462 2680 1.9 - - - 1342 2480 2.0 - - - 1242 2300 2.1 - - - - 2120 2.2 - - - - 1950 2.3 - - - - 1800 2.4 - - - - 1650 Table 23 gives an indication only of the safe load, in Kg, that may be carried between the above restraints by single BS EN 10255 (ISO 65) tubes when used as uprights. At loads greater than 900Kg* consideration must be given to set screw slip (*rating includes a safety factor of 2:1.74). Table reflects a safety factor of 2:1

49. www.keesafety.com 49 Copyright © Kee Safety Ltd. All Rights Reserved. Table 26: Load tables (Kg) – uprights restrained both ends Above values have a safety factor of 2 built into them and are based on the limit state of the material used. Table 26 gives an indication only of the safe load, in Kg, that may be carried between the above restraints by single tubes to BS EN 10255 (ISO 65) when used as uprights. At loads greater than 770Kg consi deration must be given to grubscrew slippage (a safety factor of 2 being included in this instance). Table reflects a safety factor of 2:1 Height (m) Fitting Size 6 7 8 9 Tube Size (mm) 25 N.B. 32 N.B. 40 N.B. 50 N.B. Grade of Material – 6082 T6 Aluminium 0.30 3549 5052 6063 8300 0.40 3371 4789 5906 8123 0.45 3160 4723 5722 8053 0.50 2625 4393 5512 7841 0.60 2399 4174 5249 7700 0.70 2009 3778 5118 7417 0.75 1750 3405 4803 7064 0.80 1378 2965 4147 6994 0.90 1215 2592 3622 6605 1.00 1102 2240 3360 6181 1.05 940 1933 3097 5828 1.10 843 1845 2703 5474 1.20 - 1538 2493 5122 1.30 - 1427 2231 4768 1.40 - 1318 1969 3956 1.45 - 1208 1785 3814 1.50 - 1076 1627 3461 1.60 - 988 1522 3108 1.67 - - 1443 2755 1.75 - - 1286 2543 1.80 - - 1181 2402 1.90 - - - 2296 2.00 - - - 2155 2.05 - - - 2048 2.10 - - - 1801 2.20 - - - 1730 2.30 - - - 1589 2.40 - - - 1519 Table 25: Load tables (Kg) – unfixed upright bases Above values have a safety factor of 2 built into them and are based on the limit state of the material used. Table 25 gives an indication only of the safe load, in Kg, that may be carried between the above restraints by single tubes to BS EN 10255 (ISO 65) when used as uprights. At loads greater than 770Kg consi deration must be given to grubscrew slippage (a safety factor of 2 being included in this instance). Table reflects a safety factor of 2:1 Height (m) Fitting Size 6 7 8 9 Tube Size (mm) 25 N.B. 32 N.B. 40 N.B. 50 N.B. Grade of Material – 6082 T6 Aluminium 0.30 2431 4174 5249 7382 0.40 1653 3470 4593 6994 0.45 1296 2636 3675 6640 0.50 891 1977 3150 5934 0.60 502 1538 2441 5122 0.70 405 1274 1969 3850 0.75 324 725 1706 3355 0.80 267 593 1260 2755 0.90 251 505 1129 2402 1.00 210 461 997 2048 1.05 178 395 525 1942 1.10 - 351 499 1589 1.20 - 329 394 1448 1.30 - 308 381 1271 1.40 - 285 357 742 1.45 - - 314 600 1.50 - - 276 557 1.60 - - - 530 1.67 - - - 466 1.75 - - - 441 1.80 - - - 406 1.90 - - - 369 2.00 - - - 351

30. Safety Components Catalogue 30 Copyright © Kee Safety Ltd. All Rights Reserved. Neoprene Gaskets g askets are available to prevent the corrosion associated with lime in concrete. The gaskets have more resistance than natural rubber to sunlight, ozone and oxidation. Neoprene is heat resistant and does not soften as natural rubber does under severe exposure. g asket part numbers correspond to Kee L I te flange and base components as follows: LG58 LG61-8 LG62-8 LG68-8 LG70-6 LG148-9 LG152-7 LG61-6 LG62-6 LG68-6 LG69-7 LG70-7 LG150-8 LG152-8 LG61-7 LG62-7 LG68-7 LG69-8 LG70-8 LG152-6 LG164-8 475 a luminium Wall Bracket Designed to provide attachment for a smooth handrail which complies with DDA. Countersunk 6mm diameter holes are provided for mounting. Designed for use with size 7 tube. Ø indicates diameter of fixing holes in mm. T y PE Tube ref. mm Kg D E F G Ø 475-40 7 89 6 80 83 7 0.26 D E F G

47. www.keesafety.com 47 Copyright © Kee Safety Ltd. All Rights Reserved. Length (m) Fitting Size 5 6 7 8 9 Tube Size 26.9mm x 2.6 33.7mm x 3.2 42.4mm x 3.2 48.3mm x 3.2 60.3mm x 3.6 0.3 1720 2950 4038 4783 7044 0.4 1435 2617 3703 4446 6661 0.5 1150 2284 3368 4109 6278 0.6 910 1951 3033 3772 5895 0.7 725 1618 2690 3435 5512 0.8 590 1348 2363 3098 5129 0.9 480 1128 2028 2761 4746 1.0 - 948 1752 2424 4363 1.1 - 798 1524 2134 3980 1.2 - - 1340 1884 3597 1.3 - - 1188 1668 3253 1.4 - - 1066 1484 2951 1.5 - - - 1328 2681 1.6 - - - - 2441 1.7 - - - - 2226 1.8 - - - - 2032 1.9 - - - - 1857 2.0 - - - - 1697 Table 22: Load table (Kg) – unfixed upright Table 22 gives an indication only of the safe load, in Kg, that may be carried between the above restraints by single tubes to BS EN 10255 (ISO 65) when used as uprights. Table reflects a safety factor of 2:1 Galvanised Racking Load t ables Table 21 gives an indication only of the safe load, uniformly distributed, in Kg, that may be carried per shelf consisting of front and back pipes when used as continuous beams. Span (m) Fitting Size 5 6 7 8 9 Tube Size 26.9mm x 2.6 33.7mm x 3.2 42.4mm x 3.2 48.3mm x 3.2 60.3mm x 3.6 0.5 540 1060 1750 2380 4000 0.6 435 850 1407 1870 3250 0.7 375 730 1207 1595 2760 0.8 330 645 1063 1385 2420 0.9 295 579 946 1230 2160 1.0 265 525 850 1110 1950 1.1 240 478 770 1013 1775 1.2 219 438 705 930 1625 1.3 202 403 651 858 1497 1.4 187 373 604 796 1387 1.5 175 347 564 741 1290 1.6 - 325 529 693 1205 1.7 - 306 499 650 1129 1.8 - 290 472 613 1061 1.9 - 277 448 581 999 2.0 - 268 427 553 987 2.1 - - 408 528 944 2.2 - - 391 505 855 2.3 - - 376 485 818 2.4 - - 362 467 785 2.5 - - 349 450 755 2.6 - - - 434 728 2.7 - - - 419 703 2.8 - - - 405 680 2.9 - - - - 659 3.0 - - - - 639 3.1 - - - - 620 3.2 - - - - 603 3.3 - - - - 588 3.4 - - - - 575 3.5 - - - - 564 Table 21: Beam load tables (Kg) Table reflects a safety factor of 1.67:1 Load (Kg) For uneven load distributions or single span s, the required tube size must be determined by standard bending moment calculations assuming a Kee K L a MP joint to give a simply supported beam. a t loads greater than 900Kg consi deration must be given to set screw slip. Load t ables

51. www.keesafety.com 51 Copyright © Kee Safety Ltd. All Rights Reserved. A full design and installation service to ensure compliance with all major standards and statutory requirements. Cost e stimates Specific to Project Needs t echnical a dvice and Support Site Inspection Service Design Solutions in C a D Installation Services to Meet y our Site Deadlines Kee Safety has dedicated construction professionals who have worked within the construction industry for many years. Together with their expert industry knowledge and our safety product ranges, our team is fully capable of providing you with safety guardrail and handrail solutions that will service your project needs. Whether dealing with new, refurbishment or upgrading of existing structures and developments, we can provide safety compliant guardrail and handrail designs, whether it be internal, external, at ground level, or roof level. We can also advise you on project costs, manage completion time scales from inception to meet your site requirements, and also ensure compliance of our systems with current Building Regulations and Safety requirements. t he Design and Installation Division of Kee Safety An Inspection Scheme offering a range of services, from working at height assessments to fixing pull-out tests. t he Inspection and a ssessment Service from Kee Safety Kee CH e CK is an Inspection Service Scheme offered by K ee S afety on an annual basis for new and existing roof top protection systems. Our trained inspection representatives can inspect and assess all roof top installation works which have been carried out using K ee S afety products. The inspection representative will check that all fall protection systems in place comply with current h ealth and Safety legislation regarding w orking at h eights and National and European Design Standards. In addition we offer a full w orking at h eight Assessment Service to your roof top areas. w e will inspect and issue a full report indicating the potential h ealth and Safety hazards identified on your roof areas, and provide our recommendations on solutions to overcome future hazards and potential injuries. Both our K ee CH e CK Inspection Service Scheme and our w orking at h eight Assessment Service will give you peace of mind and ensure that all your roof top protection systems comply with current h ealth and Safety regulations. Inspection Service Scheme Inspection of Roof t op Protection Systems Identification of Health and Safety Hazards Recommendation of Possible Solutions Compliance with Health and Safety Legislation t urnkey Safety Solutions

37. www.keesafety.com 37 Copyright © Kee Safety Ltd. All Rights Reserved. Meet every Safety Loading Standard up to 1500 Newtons per Metre (N/m) in practically every location Safety Barrier Systems Simple to Design and Specify The modular Kee S afety systems securely join standard sizes of structural tube in almost any configuration you can imagine. Assembled on site, K ee S afety guardrailing will accommodate most variations between design drawings and site requirements. Cost- e ffective to Install Low skill, no welding, no special tools required. All components slip over tube, and can be adjusted to the required level and positioned before tightening with a simple hex key. Widest Range of Components for Structural t ube Just sketch out the guardrail you want to construct and check the fittings you require. Combination fittings optimise the strength to weight ratio and cost of any structure, enabling different diameters of tube to be used. Meet Specified Loadings up to 1500 N/m Use the Loading Tables on page 39 to select the appropriate tube size, grade, and the ‘bay size’ for the guardrailing uprights. The same design loading can be achieved by using either stronger uprights and wider bays, or lighter uprights set closer together. Unrivalled t echnical Support K ee S afety offer practical assistance over the telephone or by fax, or, if required, will check your designs or drawings for compliance with current Safety Standards. Kee Safety Technical Support Tel: +44 (0) 118 931 1022 Fax: +44 (0) 118 931 1146 Email: sales@keesafety.com www.keesafety.com

35. www.keesafety.com 35 Copyright © Kee Safety Ltd. All Rights Reserved. For customers who need handrail installations complying with the Disability Discrimination Act (DDA) and at the same time wish to achieve a more aesthetic look, K ee S afety offers alternative connection joints, 410-8 and 418-40. Both components are made from aluminium and can be used on new or retrofitted structures. a lternative a luminium Solutions for DD a Handrails 410-8 Upright Connector Upright connector for 418-40 h andrail Bracket. Made from h igh g rade Aluminium Alloy. Connects to upright with an M6 BoxBolt. T y PE Tube ref. mm A E F Kg 410-8 8 44 40 0.08 T y PE Tube ref. mm Kg A B D F 418-40 7 8 27 85 0.14 418-40 Handrail Bracket Handrail Bracket used with 410-8. Made from h igh g rade Aluminium Alloy. h andrail tube secured to bracket by means of either rivets or self-tapping screws. Photo images (2 or 3) to go here... F E F D

42. Safety Components Catalogue 42 Copyright © Kee Safety Ltd. All Rights Reserved. Shelving Using t ype 46 or L46 Shelving with carrying rails positioned on the outside of the upright. Fitting Size x (mm) 4 –98 5 –134 6 –162 7 –196 8 -228 9 –276 Table 9 Pallet Racking Using t ype 46 or L46 Pallet racking with the carrying rails on the inside of the upright. Table 11 gives dimension ‘x’ which must be subtracted from the overall width of the carrying rails, to give the length of the cross rail in the formula: I = L – x. (Dimension x accounts for the use of two Type 46 or L46 fittings.) Table 12: Additional tube length to reach topmost fitting’s termination Table 9 gives the dimension ‘x’ to be subtracted from overall shelf width ‘L’ to give the length of the cross rail in the formula I = L – x. (Dimension x accounts for the use of two Type 46 or L46 fittings.) Construction of Braces and Struts Using t ypes C50, C51, C52 & C53 or LC50, LC51 & LC52 Fitting Size x (mm) 4 – 14 5 – 25 6 – 25 7 – 25 8 – 25 9 – 32 Table 10 Table 10 gives details of dimension ‘x’ to be subtracted to give the tube length required for use with two Type F50 or LF50 fittings in the formula l – L – 2x. Note: Dimension ‘L’ is the length from pivot point to pivot point. The distance from upright to upright is dependent on the angle of the strut. Table 11 Fitting Size x (mm) 4* –48 5* –59 6* –72 7 –85 8 –102 9 –126 The length of the longitudinal member can be calculated from multiples of the length of the bay between the centres of uprights, plus dimension ‘z’ in Table 12. Dimension z accounts for the length of tube needed to go through the topmost fitting to the fitting’s termination. This also applies to constructions using fitting Type 45. *Pallet racking is not recommended in less than size 7 tube. Fitting Size z (mm) 3 +24 4 +28 5 +31 6 +38 7 +46 8 +51 9 +61 Spigots can be either tubes or rods, riv eted into position, or the Type 18 fitting. When using the latter, a gap of 20mm must be allowed for the set screw fixing. When using multiple tube sizes in one structure, Types F50-5 to F50-9 or LF50-6 to LF50-8 can all be combined with: M50-5 to M50-9 M51-5 to M51-9 M52-5 to M52-8 M53-8 to construct combination fittings (i.e. C50-75, C50-85, C51-655, C52-855 and C53-888). LM50-6 to LM50-8 LM51-6 to LM51-8 LM52-6 to LM52-8 Longitudinal tubes are joined using fittings Type 14 or 18 couplings (use of Type 18 is not recommended as a load bearing joint), which must be positioned to occur at the edge of the Type 46 fitting, and must not all occur in the same bay at alternate levels.

45. www.keesafety.com 45 Copyright © Kee Safety Ltd. All Rights Reserved. Wire Mesh Infill Infilling is normally constructed from 50mm x 50mm x 3.2mm, 25mm x 25mm x 3.2mm or 50mm x 25mm x 3.2mm wire mesh welded to a 8mm rod frame, and is fixed into position using standard Fitting Types 81 and 82. (NB: Types 81 and 82 require cut outs on mesh less than 32mm square.) Table 19 gives the dimensions to be subtracted from the centre dimensions ‘L’ and ‘D’ of the structure to give the formulae I = L – x and d = D – x. Fitting Size x (mm) 5 –60 6 –76 7 –86 8 –89 9 –98 Table 19 Wa RNING : The spacing of panel clip Types 81 and 82 should not exceed 450mm centres. The safety attachment incorporated in the panel clip Types 81 and 82 cannot be used with mesh less than 32mm. t ube Bending Table 20 gives details of standard radius ‘R’ of the tube bent by Kee Safety Ltd. If the standard radii below are not suitable, tube sizes 5 to 9 can be rolled to any radius above a minimum of 500mm. Fitting Size R (mm) 3 57 4 57 5 90 or 98 6 102 7 135 8 152 9 203 Table 20 Type 45 can be considered if a crossover joint is acceptable. No facility for joining tubes inside fitting. 25 26 45 10 16 Tubes can be joined within the fitting. 10 25 14 18 Requires a longer tube. Fitting 84 can be used instead of the 77. 15 10 77 Requires a longer tube. Fitting 84 can be used instead of the 77. 20 21 77 Requires a longer tube. Fitting 84 can be used instead of the 77. 20 19 77 Only acceptable if the horizontal tubes are not required to be at the same level. Choice of angles. Joint less rigid. 21 10 10 No facility for joining tubes inside the sleeve. 25 10 + + + + Less rigid. Can be added to structure after assembly. Internal joint. Joint less rigid. f itting a lternatives

44. Safety Components Catalogue 44 Copyright © Kee Safety Ltd. All Rights Reserved. How to Make Jigs for Railing Posts Set-up Step 1: Start with pre-cut tube. Step 2: Measure and locate fittings on first post only. Step 3 : Lay post horizontal, and insert two pieces of scrap tube. This is all that’s involved in setting up your jig! From this point, duplicate posts can be produced by unskilled labour, without further measuring, at the rate of 20–30 posts per hour. Step 1: Set top and middle fittings in place, unfastened, on the two pieces of scrap pipe. Utilising Jigs for Ra iling Posts Production Step 2: Insert pre-cut tube into fittings, then add flange. Step 3: Simply tighten set screws, then lift off. Pedestrian Guardrailing Using t ypes 90, 91, 92, 93 and 95 This construction is used when individual rails are required to be removable and when the site is not straight and level. Slopes of up to 7° or radii greater than six metres can be accommodated without bending the tubing. When bending the tube around a corner, a Type 95 PGR spigot must be included to prevent sagging. Holes of 15mm diameter must be drilled through both walls of the upright, one at 25mm from the top of the upright tube. Table 17 gives details of: (i) Dimension ‘x’ in the formula I = L – 2x for calculating the rail lengths where: L = distance between the centres of the uprights I = length of the horizontal tube. (ii) Dimension ‘y’ in the formula h = H + y + (ground fixing) for calculating the upright length where: H = distance from ground to the centre line of the top rail h = length of upright tube. Fitting Size x (mm) y (mm) 8 –66 +25 Table 17 A brass drive screw (No. 6 x 10mm) is located at dimension ‘z’, in Table 18, on one end only for each horizontal tube. This positions the horizontal tube within the Kee Klamp fitting to give location relative to the set screws. Fitting Size z (mm) 8 37 Table 18

2. Copyright © Kee Safety Ltd. All Rights Reserved. Safety Components Catalogue Copyright © Kee Safety Ltd. All Rights Reserved. No part of this publication may be reproduced in any form without prior written permission from Kee Safety Ltd 2 Safety Kee Safety regularly monitors all new safety standards and directives to ensure the highest protection. Our systems not only meet but also exceed the current safety requirements and our components comply with the latest UK Building Regula - tions and European Standards. Quality Quality is the overriding priority when manufacturing Kee Safety components. Fittings are manufactured to strict specifications and T ü V certified for strength, manufacturing quality and consistency. Solutions From simple protection for loading bays or safety walkways in factories, to safety barriers in aggressive coastal environments or the protection of road bridges and culverts, Kee Safety provides the strategic integrated solution to give you abso - lute confidence in your safety requirements. Kee Safety is a leading global supplier of components and bespoke safety systems. Our systems are quick and easy to design and install, and are very cost effective due to the modularity of their parts. The principle is simple yet highly effective, proven over 75 years in thousands of completed projects across the globe. w hether you need to separate people from hazards or protect your equipment on site, Kee Safety offers the most cost effective, flexible and safe solutions to your barrier requirements. An innovative product for the construction of steel tubular structures. K ee KL a MP fittings are pre-galvanised cast iron for strength and corrosion resistance. Fittings manufactured from a polished high grade alu - minium alloy for the construc - tion of lightweight tubular structures. K ee LI te fittings offer superior corrosion resistance, strength and durability. A range of galvanised cast iron fittings suitable for stairs, ramps and walkways specially designed to meet all DDA requirements and Building Regulations. t he K ee Safety Concept

46. Safety Components Catalogue 46 Copyright © Kee Safety Ltd. All Rights Reserved. 46 45 10 Only acceptable if the horizontal tubes are not required to be at the same level. Choice of angles. Joint less rigid. 26 Type 27 can be substituted by a Type 29 used vertically, between 30° to 60°. 27 29 Type 28 can be substituted by a Type 30, between 30° and 45° only. 28 30 The joint is less rigid. 29 C50 Must be machined out to required angle. 30 28 Only suitable if the horizontal tubes are not required to be at the same level. Choice of angles. Joint less rigid. 35 26 10 Only suitable if the horizontal tubes are not required to be at the same level. Choice of angles. Joint less rigid. 40 26 26 Joint less rigid. 45 17 Only suitable if the clips are not required to be at the same level. 82 81 Only suitable if the fixings are not required to be in line. M51 M50 Only suitable if the fixings are not required to be in line. M52 Interchangeable if the design features acceptable. 59 60 Only substitute Type 62 and bend tube. 63 62 Interchangeable depending on most convenient fixing plate arrangement. Fitting 65 is only available in size 6. 64 65 Type 70 can be substituted with Types 10 & 61 with stub of tube. 70 10 61 Type 70 can be substituted with Types 114 & 61. 70 114 61 Not for connecting tube. 75 14 + + + + + + Only suitable if the horizontal tubes are not required to be at the same level. Choice of angles. 61 62 10 10 + M50 M50 + M50 81 115 265 68

36. Safety Components Catalogue 36 Copyright © Kee Safety Ltd. All Rights Reserved. In-fill Panels Panels in a variety of materials, sizes and finishes. The standard 50mm x 50mm Weld Mesh is available in either g alvanised or Powder Coated finish. Maximum panel size is 240cm x 120cm. Smaller opening are also available (25mm x 25mm or 50mm x 50mm). K ee S afety also offer made-to-order Vertical Bar Infill which is stronger than welded mesh and is normally fabricated from 12mm solid bar welded at 100mm centres. This complies with the 100mm sphere rule stated in BS 6180:1995, Clause 5.3. Perforated or solid infill is also available. 99 Hex Key Simple hex key. A/F refers to the dimension across the flats. T y PE To suit tube sizes A/F 99-2 2 3 5/32" 99-4 4 3/16" 99-6 5 6 1/4" 99-7 7 8 9 5/16" A/F t oeboard Used with fitting Type L6 9 Railing Flange. The toeboard is 102mm high and is made of aluminium. A channel in the toeboard accepts the bolt head of the mounting hardware, allowing ease in placement. Toeboard is sold by the linear metre. It can be supplied adonised if required. Mounting hardware is available separately. TB1 Modules Preassembled modules make for a simple and quick assembly or installation of your project. Provides constant barrier heights and lengths. Made to suit individual project requirements. A standard set is also available. 97 Set Screws Socket set screws are supplied in all Kee Safety fittings as standard. All set screws are coated with our unique Kee K O at and have four times greater time and corrosion resistance than the bright zinc plated grub screws. T y PE Tube ref. Sizes A 97-2 2 5/16" BSF 97-3 3 5/16" BSF 97-4 4 3/8" BSF 97-5 5 ISO 228 1/4" 97-6 6 ISO 228 1/4" 97-7 7 ISO 228 3/8" 97-8 8 ISO 228 3/8" 97-9 9 ISO 228 3/8" 98 Ratchet Set Reversible ratchet for easier fastening of grub screws (1/2" Drive, 20cm long). Ratchet Handle and h exagon Bits are supplied separately. A/F refers to the dimensions across the flats. A/F T y PE Tube ref. Sizes A 98 Ratchet Handle (1/2" drive, 8" long) 98-5 5 Hexagon Bit (1/4" AF) 98-6 6 Hexagon Bit (1/4" AF) 98-7 7 Hexagon Bit (5/16" AF) 98-8 8 Hexagon Bit (5/16" AF) 98-9 9 Hexagon Bit (5/16" AF) a ccessories

50. Safety Components Catalogue 50 Copyright © Kee Safety Ltd. All Rights Reserved. Vibration t est Exhaustive tests on samples of standard size 7 Kee K L a MP fittings were performed by an independent research laboratory. The purpose of the test was to evaluate the use of either standard set screws or self-locking set screws. t est a rrangement A “Tee” section test assembly was made using three 300mm lengths of galvanised size 7 standard tube held together by a three socket tee fitting (Type 25-7). The vertical leg of the test assembly was supported in a standard railing flange (Type 62-7). The completed assembly was then rigidly attached to the vibration table. The test assem bly was initially assembled using standard set screws and t est Report: Vibration of Kee Klamp ® a ssemblies Resonance Frequencies Q Factor Running Time 74 1.27 Nil 106 1.27 Nil 158 1.53 6 hours 200 1.8 6 hours 221 5 6 hours 295 9 6 hours Table 27: Test Results tested in this configuration. The standard set screws were then replaced with the self-locking screws and the tests repeated. t est Procedure The test was conducted on a Ling 667Kg Electromagnetic Vibration Table. The table was programmed to perform a resonance search between 25 and 350Hz and resonant frequencies were recorded and shown in Table 27. During the resonance search, amplification factors (Q) were measured at each resonant frequency, the point of reference being the end of one horizontal tube. The table was then held at one of the resonant frequencies, set in motion with a controlled acceleration level of 4g, and ran for a period of six hours. This was repeated for three more resonant frequencies in descending order of Q factor. During the twenty-four hours of vibration at the four resonant frequencies above, no signs of loosening with either type of attachment screw occurred. Size 9 heavy Will accept 8 heavy or medium Size 9 medium Will accept 8 heavy or medium Size 8 No telescopic relationship Requires special spiggoting material Size 7 heavy Will only accept size 6 light Size 7 medium Will accept size 6 light, medium and heavy Size 6 heavy No telescopic relationship Requires special spiggoting material Size 6 medium Will only accept size 5 light Size 5 heavy No telescopic relationship Requires special spigotting material Size 5 medium No telescopic relationship Requires special spigotting material Size 4 No telescopic relationship Requires special spigotting material Size 3 No telescopic relationship Requires special spigotting material Size 2 No telescopic relationship Requires special spigotting material Table 28: The telescopic relationship between tubes to BS EN 10255 (ISO 65)

7. www.keesafety.com 7 Copyright © Kee Safety Ltd. All Rights Reserved. Ty PE Tube ref. mm Kg A D E F 12-5 5 35 72 35 0.30 12-6 6 44 85 35 0.43 12-7 7 55 94 40 0.71 12-8 8 60 108 40 0.92 E F D 45° A A 12 45° Single Socket t ee Engineered to create 45° angles. This component is most frequently used for bracing and struts. T y PE Tube ref. mm Kg A D E F A12-8 8 60 122 52 1.07 A A D E F 45° A 12 Split 45° Single Socket t ee The unique hinge and pin system of this fitting enables existing structures to be easily extended without the need for dismantling. This fitting is most frequently used for bracing and struts. 10 Ty PE Tube ref. mm Kg A B D E 10-2 2 2 25 19 0.02 10-3 3 3 29 25 0.07 10-4 4 4 84 32 0.13 10-5 5 5 41 37 0.23 10-6 6 6 46 47 0.29 10-65 6 5 44 37 0.25 10-67 6 7 55 55 0.43 10-7 7 7 60 55 0.45 10-75 7 5 57 37 0.32 10-76 7 6 57 46 0.43 10-78 7 8 73 60 0.63 10-8 8 8 68 60 0.62 10-87 8 7 63 55 0.50 10-9 9 9 84 73 0.97 10-98 9 8 74 64 0.65 Single Socket t ee Designed to give a 90 degree butt joint between two tubes. Frequently used for the joint between uprights and the middle rail on guardrailing where the railing site is straight and level. Also used for base ties on racking. This fitting cannot be used where the tubing within the sleeve is required to be joined within the fitting. Type 25 should be used when a join in the tube is necessary. A E D B T y PE Tube ref. mm Kg A D E A10-7 7 60 28 0.57 A10-8 8 88 33 0.89 D E A A A 10 Split Single Socket t ee Designed to allow additions or extensions to existing structures without the need for dismantling. Tube must not be joined within the fitting. Fitting has strength and function comparable to Type 10 components. T y PE Tube ref. mm Kg A D 14-4 4 58 0.14 14-5 5 77 0.27 14-6 6 89 0.39 14-7 7 102 0.52 14-8 8 104 0.64 14-9 9 124 1.08 D A 14 Straight Coupling Designed to form an in-line joint between two pieces of tube of the same size. w here a constant diameter is required along the outside of the tube (such as DDA handrail or garment storage) an internal spigot (Type 18) should be considered. A

33. www.keesafety.com 33 Copyright © Kee Safety Ltd. All Rights Reserved. 508-7 Optional Gap Washer A rubber gasket for use with size 7 components. Comes only in black. 84-848 Upright t op Cap A metal drive-in plug which is difficult to remove when installed. The 84-848 is a cap for the open ends of size 8 uprights and covers the top of a 10-848 tee fitting. Kee K L a MP Types 77-7, 77-8, 84-7 or 84-8 could also be used, but do only cap the tube, not the tube as well as the component. This fitting can only be used with EN 10255 Medium Tube. A 515-7 T y PE Tube ref. mm Kg A D 515-7B 7 34 0.84 90° Split e lbow A 90° corner elbow consisting of two separate pieces, 515-7T and 515-7B, which are joined by a centrally positioned screw. The combined fitting is positioned with the ends inside the adjoining handrails, and the outer grubscrews tightened. This forces the halves apart, gripping the inside of the tube. The central screw is then tightened, locking the fitting in place. A A D 518-7 T y PE Tube ref. mm Kg A B D E Ø 518-7 7 socket 51 30 5 0.49 Handrail Bracket An intermediate upright handrail support. This bracket is designed to be mounted on a Type 10-848, 10-848C, 26-840 and 26-840C or a Type A10 fitting; the rail sits on the saddle and is secured by either Ø4.8mm x 15mm long aluminium ‘multi-grip’ pop rivets or No. 10 x 20mm countersunk self-tapping screws. Ø indicates diameter of rivet holes. A B E D 514-7 T y PE Tube ref. mm Kg A D E 514-7 7 74 25 0.38 Internal Coupling Designed especially for DDA railing, this internal coupling can be powder coated (unlike our Type 18 fitting). The inset hex screw and precise coupling design allows handrail to be smooth and continuous. The internal coupling is a necessary component when installing Type 520-7, Type 554-7, Type 565-7 and Type 567-7. A A E D 520-7 90° Solid e lbow An alternative elbow to Type 515, two piece fitting. The elbow is designed to be joined to the handrails using two Type 514-7 internal couplings. T y PE Tube ref. mm Kg A D E 520-7 7 80 30 0.40 D E D A A

8. Safety Components Catalogue 8 Copyright © Kee Safety Ltd. All Rights Reserved. 15 T y PE Tube ref. mm Kg A D 15-4 4 34 0.13 15-5 5 41 0.27 15-6 6 46 0.37 15-7 7 60 0.67 15-8 8 68 0.77 15-9 9 85 1.28 90° e lbow A 90° elbow joint, most frequently used as an end joint for the top rail of safety railing on a level site. A D D A 16 T y PE Tube ref. mm Kg A D 16-5 5 50 0.29 16-6 6 52 0.33 16-7 7 68 0.59 16-8 8 73 0.60 16-9 9 90 0.92 Clamp-on t ee w idely used for adding to and modifying existing structures. This performs the same function as a Type 10, but because of its open socket, it can be added to a complete structure. For alternative fitting, see Type A10. The hex head bolt is for retaining purposes only. Torqued up to 15Nm. A A D 17 T y PE Tube ref. mm Kg A B D E 17-5 5 27 40 0.15 17-6 6 34 48 0.23 17-7 7 43 58 0.43 17-8 8 49 65 0.56 17-9 9 61 78 0.90 Clamp-on Crossover Designed to provide a 90° crossover joint. Can be added to an existing structure. Tube should not be joined within this fitting. For an alternative fitting, see Type 45 or Type A45. B A D E T y PE Tube ref. mm Kg A B D E 19-5 5 5 60 31 0.20 19-6 6 6 58 33 0.29 19-7 7 7 73 40 0.41 19-8 8 8 90 55 0.53 19-85 8 5 73 45 0.65 19-9 9 9 110 49 0.99 19 a djustable Side Outlet t ee Used in pairs to form variable angle joints between 90° and 180°. When calculating cutting lengths for tube, dimension ‘E’ should be subtracted to give true tube length. Types 19-8 and 19-85 can produce an angle range between 60° and 180°. Note: Pairs sold and priced separately in UK, France, and Germany. A B B D E 90°–180° 20 T y PE Tube ref. mm Kg A D 20-4 4 34 0.17 20-5 5 41 0.38 20-6 6 46 0.48 20-7 7 60 0.81 20-8 8 68 1.13 20-9 9 84 1.82 Side Outlet e lbow A 90° corner joint most frequently used for the top rail of safety railing. It can also be considered for the corner joint of benches, work tables, and other rectangular structures. A A D D D A 18 Internal Coupling An internal spigot providing a flush joint between two tubes of the same diameter. Not as strong as Type 14 and must not be used where a direct tensile load is applied. This fitting can only be used with 3.2mm thick tube. WARNING: Type 18 coupling must not be used as a load bearing joint. A E D T y PE Tube ref. mm Kg A D E 18-6 6 76 20 0.26 18-7 7 76 20 0.38 18-8 8 95 20 0.54 A Note: This fitting can only be used with tube wall thickness 3.2 mm

32. Safety Components Catalogue 32 Copyright © Kee Safety Ltd. All Rights Reserved. A 10-748 a dd-on Single Handrail Socket 32mm The unique "hinge and pin" system of this socket tee enables existing structures to be easily modified without the need for dismantling. Hinges around existing size 7, or 32 N.B. tube. A 10- 848 a dd-on Single Handrail Socket The unique “hinge and pin” system of this socket tee enables existing structures to be easily modified without the need for dismantling. Hinges around existing size 8, or 40 N.B. tube. A B A A B A T y PE Tube ref. mm Kg A B D E A10-848 8 stub 82 55 0.30 10-840 C T y PE Tube ref. mm Kg A B D E 10-840C 8 stub 55 85 0.41 Single Handrail Socket Capped Capped 90° socket tee designed for use at the termination of an upright where a handrail socket needs to be joined. A A 10-848 Single Handrail Socket A ‘tee’ component used for new builds as an interface between uprights and the K ee aCC e SS fittings. For upgrading size 7 and size 8 systems see A10-748 and A10-848. B A A T y PE Tube ref. mm Kg A B D E 10-848 8 stub 55 85 0.38 26-840 T y PE Tube ref. mm Kg A B D E F 26-840 8 stub 55 48 110 0.44 B A B A 26-840 C T y PE Tube ref. mm Kg A B D E F 26-840C 8 stub 55 48 110 0.50 t win Handrail Socket Capped Capped fitting for use at the termination of an upright to create two handrail sockets at 90° from the upright. A B B t win Handrail Socket Fitting slips over upright to create two handrail sockets at 90°. T y PE Tube ref. mm Kg A B D E A10-748 7 stub 76 53 0.28 D E D E D E F D E E D F D E

43. www.keesafety.com 43 Copyright © Kee Safety Ltd. All Rights Reserved. Base and Wall f ixings* Flange Type x (mm) 59 –10 60 –10 61 –6 62 –6 67 –6 Table 13 Constructing Circles and t riangles Slopes and radii pr esent no problem to the Kee K L a MP galvanised railing systems. Fitting Types 27, 28, 29, 30, C50, C51, C52, 55, 56, 86, 87, 88 and 89 (and the 90 range pedestrian guardrail fittings) are designed to allow for raked handrail while keeping the uprights vertical. Tube can be bent and radi - used to suit most situations. Also, true lengths have to be determined where braces and struts are being used. To enable Kee Safety to mach ine fittings and radius tube some basic information is required (e.g. angle of slope, arc lengths, etc.). We have provided simple formulae and worked examples to help you solve individual problems. Machined f ittings Types 27 and 28 are held in stock as blanks. These are then machined to individual requirements. It is therefore essential when ordering that the required angle from the horizontal is stated. Other tube lengths need to be determined when using fitting Types 29 and 30, C50, C51 and C52 and the 90 range pedestrian guardrail fittings. Worked e xample Consider the following con crete single flight staircase. Table 13 gives details of the ground fixing dimension ‘x’, to be subtracted from the height ‘H’ to give the length of the upright ‘h’. Table 14 gives details of the ground fixing dimension ‘x’, for Type 63-6 only, to be subtracted to give the length of the upright for each angle condition. Angle x (mm) 45 ° –38 50 ° –32 60 ° –25 65 ° –12 Table 14 Type 59 Type 60 Type 61 L61 Type 62 L62 69 L69 Type 63 (size 6 only) Type 64 65 L164 (size 6 only) x x 3° to 11° Type 66 Type 67 Type 68 L68 115 265 Table 15 gives the dimension ‘x’ to be subtracted from the length of the up - right for fitting Types 64, 65, 67, 68, 115, 265, L68 and L164. Fitting Size x (mm) 6 –5 7 –6 8 -6 Table 15 Table 16 gives the ground fixing dimension ‘x’, to be added to the upright member to allow for the setting into the socket Type 66. Fitting Size x (mm) 6 +115 7 +127 8 +127 Table 16 w here H = Vertical height from 1st nosing to last nosing. h = Vertical height from ground level to 1st nosing. I = Horizontal dimension from 1st nosing to last nosing. L = Hypotenuse dimension (Pitch Line) from 1st nosing to last nosing. Known Data Formula for Side and Angle H & L I = √ (L 2 – H 2 ) Sin B = – C = 90° – B L & I H = √ (L 2 – I 2 ) Sin C = – B = 90°– C H & I H = √ (H 2 – I 2 ) Tan B = – C = 90° – B H L I L I H Note: The table can be used to solve angles and true lengths for braces and struts. Step 1 From a simple site survey or information from a working drawing, obtain the following dimensions. Note: For greater accuracy, ve rtical dimensions should be taken by means of a Dumpy Level or a Theodolite. H = vertical height from the 1st nosing to the last (140cm). L = pitch line, the diagonal dimension from the 1st nosing to the last (240cm). Step 2 From the table to determine angle B we use; Sin B = 55 / 96, Angle B = 35° Ramps can be dealt with in a similar way. Most ramps have a stated gradient (e.g. 1:12); for every 12 units traversed horizontally, 1 unit of vertical height is obtained. * w hen using Kee L I te bases and flanges, "ground fixing" dimension (x) will be zero, except when using flanges L164, L68 and LC58.

4. t ÜV a pproval Kee Safety components are approved by TÜV, Europe’s leading independent testing house. The maximum load of each fitting type is as stated on the TÜV Certificate, a copy of which is available upon request. For an up-to-date T ü V listing see our website at www.keesafety.com. Safety Components Catalogue 4 Copyright © Kee Safety Ltd. All Rights Reserved. Copyright © Kee Safety Ltd. All Rights Reserved. KEE KLAMP tube size Tube diameter (mm o.d.) Nominal bore* (mm) 2 13.5 8 3 17.5 10 4 21.3 15 5 26.9 20 6 33.7 25 7 42.4 32 8 48.3 40 9 60.3 50 t ube for your Structure Kee S afety components are produced in a range of standard sizes to suit steel tubing to BS EN 10255 (ISO 65), medium and heavy gauge, from 13.5mm to 60.3mm outside diameter; also equivalent sizes of tubing in other materials. Tubing of other specifications can be used, providing the steel is compatible with BS EN 10255 (ISO 65) and wall thickness is not less than 3.2mm. Galvanised Steel K ee KL a MP and K ee a CC e SS components are supplied hot dip galvanised to BS EN ISO 1461. Powder Coating Durable, polyester coating applied to already galvanised/polished products; available in any RAL colour. a luminium K ee LI te components are made from high grade Aluminium Silicon Magnesium Alloy. a nti-Bacterial Coating Defence against the growth of potentially harmful invisible bacteria and fungi; this powder coating can be applied in a wide range of RAL colours. R a L Colours The broad colour range offers a variety of visual contrast options. These colours will enhance any handrail, guardrail, balustrade or a multitude of applications. Note: Kee Safety can provide general guidance on the use of the fit - tings detailed in this catalogue. However, the nature of the product means that the ultimate responsibility for selecting the correct fitting for an application rests with the customer. The customer should also ensure that any existing structure to which a Kee Safety component is being secured is of sufficient strength to support both the weight of the Kee Safety construction and the imposed loads applied, including wind loads, snow loads and any other superimposed loads. 7 44 mm 42.4 mm 32 mm N.B. 6 35 mm 33.7 mm 25 mm N.B. 5 28 mm 26.9 mm 3 19 mm 17.5 mm 10 mm N.B. 2 14 mm 13.5 mm 8 mm N.B. 4 23 mm 21.3 mm t echnical Information *Nominal bore is an arbitrary dimension, because the bore varies with the wall thickness of the tubes. 20 mm N.B. 15 mm N.B.

26. Safety Components Catalogue 26 Copyright © Kee Safety Ltd. All Rights Reserved. L M50 Male Single Swivel Socket Member The male portion of a swivel component combination. The fitting can also be used to attach flat panels to tubular structures. A E D F G L 46 Combination Socket t ee and Crossover Used on racking to join horizontal carrying rails to the upright, leaving the socket to take a horizontal tube outside the upright. On pallet racking, it is preferable to have the carrying rails inside the upright. A A A E D E F H G T y PE Tube ref. mm Kg A D E F G H L46-6 6 42 40 52 44 50 0.19 L C50 Single Swivel Socket A complete combination swivel fitting, variable through 170°. Note: Swivel fittings are not designed to resist bending loads. A structure should not be designed entirely of swivel fittings as they will not provide sufficient stability for the structure. A B T y PE Tube ref. Kg A B LC50-66 6 6 0.31 LC50-77 7 7 0.44 LC50-88 8 8 0.53 85 ° L F50 f emale Singe Swivel Socket Member The female part of a swivel component combination. A F D G E T y PE Tube ref. mm Kg A D E F G LF50-6 6 50 42 75 53 0.17 LF50-7 7 59 53 90 59 0.25 LF50-8 8 65 60 90 67 0.29 T y PE Tube ref. mm Kg A D E F G Ø LM50-6 6 50 44 47 11 10 0.12 LM50-7 7 59 51 50 11 10 0.15 LM50-8 8 65 60 55 11 10 0.20 L C51 Double Swivel Socket Complete combination fitting. Reducing combinations of Type LC51 are available in sizes 6, 7 and 8. A C B 85 ° 85 ° L M51 Male Double Swivel Socket Member One half of a combination component. This component can also be used for attaching flat panels to tubular structures. A E D G F H T y PE Tube ref. mm Kg A D E F G H Ø LM51-6 6 50 44 47 11 42 10 0.16 LM51-7 7 59 51 50 11 53 10 0.20 LM51-8 8 65 60 55 11 60 10 0.27 T y PE Tube ref. Kg A B C LC51-666 6 6 6 0.57 LC51-777 7 7 7 0.73 LC51-888 8 8 8 0.85

11. Copyright © Kee Safety Ltd. All Rights Reserved. www.keesafety.com 11 A 40 T y PE Tube ref. mm Kg A D E F A40-8 8 60 88 55 1.96 Split f our Socket Cross The unique hinge and pin system of this fitting enables existing structures to be easily extended without the need for dismantling. This fitting is most frequently used in multiple upright structures to tie a centre upright with horizontal tubes in four directions. The upright passes through the fitting. A A A A A D E F 45 T y PE Tube ref. mm Kg A B D E 45-2 2 2 16 19 - 0.02 45-3 3 3 21 25 - 0.07 45-4 4 4 25 28 - 0.15 45-5 5 5 34 31 - 0.20 45-6 6 6 40 38 - 0.34 45-65 6 5 36 41 37 0.29 45-7 7 7 55 46 - 0.54 45-76 7 6 45 46 38 0.45 45-8 8 8 55 50 - 0.59 45-86 8 6 48 51 38 0.45 45-87 8 7 51 51 46 0.55 45-9 9 9 67 61 - 0.91 45-98 9 8 60 75 73 1.09 Crossover Designed to give a 90° crossover joint. Frequently used on safety railing where, to reduce cost by minimising the tube cuts, a continuous horizontal rail is used. Tube cannot be joined within this fitting. It may also be used to give intermediate levels on racks, etc. when horizontal ties between uprights are not required. Note: Where dimension ‘E’ inidcates two figures, the first figure refers to socket ‘A’ and the second refers to socket ‘B’ in the table. D E A B A 45 T y PE Tube ref. mm Kg A D E A45-7 7 49 46 0.65 A45-8 8 55 50 0.79 Split Crossover The unique hinge and pin system of this fitting enables existing structures to be easily extended without the need for dismantling. This fitting is designed to give a 90° offset crossover joint. Tube should not be joined within the fitting. Type A45 function is comparable to Type 45 fitting. A A D E Swivel f ittings T ypes F50, M50, MH50, M51, MH51, M52, M53 and M58 are known as swivel fittings and can be assembled as Types C50, CH50, C51, C52, C53 and C58, or supplied as separate items. They are frequently used for bracing but can also overcome problems where joints are required at angles other than those achieved by fixed angle fittings. For economical use of tubing, when making ‘C’ fittings, or combination fittings, Types F50 (sizes 5 to 9 only) can be combined with different sizes of Types M50, MH50, M51, MH51, M52, M53 and M58. F50-4 and M50-4 will only combine with each other. W a RNING!: An entire structure should not be constructed from swivel fittings, as they would not provide sufficient stability or rigidity in the structure. Types M50, MH50, M51, M52, M53 and M58 can also be used separately to secure various types of in-fill panel. These fittings are not designed to take bending moments. 46 Combination Socket t ee and Crossover Used on racking to join horizontal carrying rails to the upright, leaving the socket to take a horizontal tie across the section. For shelved racking it is usual to have the horizontal tube outside the upright. On pallet racking it is preferable to have the carrying rails inside the upright. A T y PE Tube ref. mm Kg A D E F 46-4 4 34 28 25 0.15 46-5 5 41 31 34 0.30 46-6 6 46 38 40 0.49 46-7 7 60 46 49 0.69 46-8 8 68 51 55 0.91 46-9 9 85 61 67 1.54 A A E F D C 50 Single Swivel Socket Complete combination fitting. Reducing combinations of Type C50 are available for sizes 5 to 9. See Types F50 and M50 for individual fitting specifications. See ‘Swivel Fittings’ at bottom of this page for more information. A 85 ° T y PE Tube ref. Kg A B C50-44 4 4 0.15 C50-55 5 5 0.56 C50-66 6 6 0.64 C50-77 7 7 0.80 C50-88 8 8 0.91 C50-99 9 9 1.22 B 85 °

34. Safety Components Catalogue 34 Copyright © Kee Safety Ltd. All Rights Reserved. B A 555-8 T y PE Tube ref. mm Kg A B D E Ø 555-8 8 7 13 89 5 0.50 t op f ix Rail a ssembly Is an in-line, adjustable angle, single top-rail mounted component for use where a guidance handrail is required and where there is no need for a twin-rail guardrail style system. Saddle has a variable angle of 60° from the vertical. Ø indicates diameter of rivet holes. A B D E 554-7 T y PE Tube ref. mm Kg A D 554-7 7 108 0.33 Variable a ngle A variable angle elbow for changes in elevation. This elbow allow for flexibility within particular designs or plans. The elbow is joined to rails using two Type 514-7 internal couplings. A A D D 30 ° –200 ° 565-7 T y PE Tube ref. mm Kg A D E F Ø 565-7 7 82 86 90 7 0.67 Wall Mounted e nd Return A wall mounted handrail return bracket. Bracket is joined to handrail using Type 514-7 coupling. Three fixing holes are drilled and countersunk to suit No. 14 csk screws. Ø indicates diameter of fixing holes. A E D F 567-7 e nd Post Handrail Return A handrail return bracket for use when mounting railing to an upright. This handrail is mounted to an upright using a handrail socket. Join the return handrail using Type 514-7 internal coupling. E D F 570-7 T y PE Tube ref. mm Kg A D E F G H Ø 570-7 7 88 63 82 90 25 7 0.67 Wall Mounted Handrail Bracket A wall mounted version of the 518-7. The handrail tube sits on the ‘saddle’ and is secured using either No. 10 self-drilling screws or multi-grip pop rivets. This bracket provides holes for countersunk head fixing screws only. Three fixing holes are drilled and countersunk to suit 6mm diameter csk screws. Ø indicates diameter of fixing holes. A 561-7 E D F H G T y PE Tube ref. mm Kg A D E Ø 561-7 7 90 40 7 0.35 Wall f lange A wall mounted hand rail end flange. Four fixing holes are drilled and countersunk to suit 6mm diameter flat head wood screws. Joins to rail with Type 514-7 Internal Coupling. Ø indicates diameter of fixing holes. A D E T y PE Tube ref. mm Kg A D E F Ø 567-7 7 82 86 90 7 0.67

18. Safety Components Catalogue 18 Copyright © Kee Safety Ltd. All Rights Reserved. 79 Sheeting Clip This fitting is used to attach profiled sheeting material to tube. The fitting is supplied with the following hardware: one M6 x 50mm roofing bolt, on M6 square nut, and one M6 lock washer. BZP finish. Ø indicates diameter of bolt hole. T y PE Tube ref. mm Kg A D E F G Ø 79-7 7 46 34 8 21 8 0.08 A G D E F 81 Single Sided Clip For attaching wire mesh infill. For economy, it is possible to use Type 81 clips without the safety attachment to secure various types of infill panels (plyboard, perspex, etc.) up to a thickness of 10mm. All clips are supplied with hexagonal head fixing bolts, M6 x 35mm long and nut. The primary clip has a slot measuring 8 x 15mm. Ø indicates diameter of the safety attachment bolt hole. T y PE Tube ref. mm Kg A D E F Ø 81-5 5 24 39 56 7.5 0.07 81-6 6 27 42 59 7.5 0.08 81-7 7 32 47 64 7.5 0.08 81-8 8 34 49 66 7.5 0.09 81-9 9 40 55 72 7.5 0.10 Note: For D and E dimensions the figures are given for the respective minimum and maximum dimensions allowed by the slotted hole. D E F 78 T y PE Tube ref. mm Kg A D E Ø 78-5 5 30 25 14 0.21 78-6 6 33 26 14 0.25 78-7 7 38 26 14 0.26 78-8 8 41 26 14 0.28 e ye f itting Used in conjunction with Type 83 fitting for gate hinges. Ø indicates diameter of pivot hole. A D E 76 T y PE Tube ref. mm Kg A D E F 76-5 5 28 25 28 0.17 76-6 6 35 25 13 0.21 76-7 7 40 25 40 0.23 76-8 8 41 25 13 0.24 Hook A fitting normally used for attachment of chains. A E D F 77 T y PE Tube ref. Kg A 77-4 4 0.001 77-5 5 0.004 77-6 6 0.007 77-7 7 0.016 77-8 8 0.020 77-9 9 0.025 Plastic Plug A grey plastic plug to fit open ended tubes. See also Type 84. Suitable for medium and heavy tubing only. 82 Double Sided Clip For attaching wire mesh infill. For economy it is possible to use Type 82 clips without the safety attachment, to secure various types of infill panels (plyboard, perspex, etc.) up to a thickness of 10mm. All clips are supplied with hexagonal head fixing bolts, M6 x 35mm long, and nut. The primary clip has a slot measuring 8mm x 15mm. Ø indicates diameter of the safety attachment bolt hole. T y PE Tube ref. mm Kg A D E F Ø 82-5 5 24 39 112 7 0.11 82-6 6 27 42 118 7 0.12 82-7 7 32 47 128 7 0.13 82-8 8 34 49 132 7 0.14 82-9 9 40 55 144 7 0.14 Note: For D and E dimensions the figures are given for the respective minimum and maximum dimensions allowed by the slotted hole. D D E E F A

27. www.keesafety.com 27 Copyright © Kee Safety Ltd. All Rights Reserved. A L C52 T y PE Tube ref. Kg A B C LC52-666 6 6 6 0.59 LC52-777 7 7 7 0.73 LC52-888 8 8 8 0.85 Corner Swivel Socket Complete combination component. Reducing combinations of Type LC52 are available in sizes 6, 7 and 8. See Type LM52 and Type LF50 for measurements. 85 ° 85 ° A B C L M52 Male Corner Swivel Socket Member One half of a combination component. This component can also be used for attaching flat panels to tubular structures. Ø indicates diameter of rivet holes. T y PE Tube ref. mm Kg A D E F G H Ø LM52-6 6 50 44 47 11 42 10 0.16 LM52-7 7 59 51 50 11 53 10 0.23 LM52-8 8 65 60 55 11 60 10 0.27 A D G E F H L M58 T y PE mm Rivet hole dia. (mm) Fixing hole dia. (mm) Kg D E F G H Ø Ø LM58 86 34 8 53 45 10 11 0.17 Swivel f lange Plate This may be considered for various wall and brace fixings, usually combined with Type LF50 to give an adjustable angle fitting Type LC58. Ø indicates diameter of holes. G D H E F L C58 T y PE Tube ref. mm Kg A Ø LC58-6 6 11 0.34 LC58-7 7 11 0.40 LC58-8 8 11 0.60 A Swivel f lange A swivel fitting for attachment of angled tube to a flat surface. See Type LM58 and Type LF50 for measurements. Ø indicates diameter of fixing holes. Note: This fitting is not recommended for use as a base flange to support guardrail or balustrades. L 61 T y PE Tube ref. mm Kg A D E F G H Ø L61-6 6 41 50 8 100 49 6 0.21 L61-7 7 53 55 8 110 61 6 0.29 L61-8 8 60 60 8 120 67 6 0.32 f lange This flange, with holes provided for countersunk head fixing screws only, is used in structures where the fixing required is positional only. Frequently used as a wall fixing bracket. Ø indicates diameter of fixing holes. WARNING!: It is not recommended for use as a base flange to support guardrail or balustrades (see Type 62). H D F L B54 T y PE Tube ref. mm Kg A D E F LB54-666 6 50 42 100 0.35 LB54-777 7 58 55 119 0.65 LB54-888 8 65 60 131 0.73 a djustable e lbow A swivel fitting designed as an in-line variable angle connection, adjustable from 45° to 200°. Nut and bolt included. F D E 45 ° –200 ° A A

14. Safety Components Catalogue 14 Copyright © Kee Safety Ltd. All Rights Reserved. A A 56 a cute a ngle e lbow Type 56 is an ideal fitting to use as an alternative to bending, or when a junction between a sloping tube and an end post is required, i.e. guardrail and staircases. (Refer to page 41 for more information.) T y PE Tube ref. mm Kg A D E F 56-8 8 134 112 112 1.45 F E D 40 °– 70 ° C 58 T y PE Tube ref. Kg A B C C58-5 5 0.70 C58-6 6 0.76 C58-7 7 0.84 C58-8 8 0.94 C58-9 9 1.07 Swivel f lange A swivel fitting for attachment of angled tubing to a flat surface. For dimensions refer to Type F50 and Type M58. WARNING!: C58 is not recommended for use as a base flange to support guardrail, balustrades or other types of structure. A 160 ° D E K D P 57 Modified M50-8 with Slot Designed for the securing of various types of panels and flooring to tube structures (i.e. plywood, plastic sheeting, wood planking, etc.). This fitting has a single offset flange to allow for the attachment of panels to tube. See Type P50. A T y PE Tube ref. mm Kg A D E F G H J K P57-8 8 61 77.5 32 22.5 9 10 11 0.30 F H J G P 57E Modified P57 This fitting is similar to the P57-8 but has an elongated offset flange with a fixing hole rather than a slot. T y PE Tube ref. mm Kg A D E F G H Ø P57E-7 7 55 103 32 86 11 6 0.37 A E F H G 55 T y PE Tube ref. mm Kg A D E 55-6 6 46 116 0.51 55-7 7 55 154 0.81 55-8 8 60 153 0.85 Obtuse a ngle e lbow The Type 55 is an ideal fitting to use as an alternative to bending, or when a junction between a sloping tube and an end post is required, i.e. guardrail and staircases. (Refer to page 41 for more information.) A D A D 125 ° –178 ° M 53 Variable a ngle Double Swivel Socket A part of a Type C53 combination fitting. Type C53 is made by combining two Type M53 and two Type F50 fittings. Ø indicates the diameter of the fixing whole. A T y PE Tube ref. mm Kg A D E F Ø M53-8 8 54 23 19 10.5 0.25 E D F

13. www.keesafety.com 13 Copyright © Kee Safety Ltd. All Rights Reserved. P 51 Modified M51-8 with Offset Slots Designed for the secure fitting of various types of panels and flooring to tube structures ( i.e. plywood, plastic sheeting, wood planking, etc.) This fitting has two offset flanges to allow the flush attachment of panels to tube. A T y PE Tube ref. mm Kg A D E F G H J K L P51-8 8 61 81 47 32 8 10 11 13 0.70 F E E D L G H J K C 52 T y PE Tube ref. Kg A B C C52-555 5 5 5 0.97 C52-666 6 6 6 1.12 C52-777 7 7 7 1.34 C52-888 8 8 8 1.55 Corner Swivel Socket Complete combination fitting. Reducing combinations of Type C52 are available sizes 5 to 8. For dimensions refer to Type F50 and Type M52. See ‘Swivel Fittings’ (bottom of page 11) for more information. A C B MH 51 Male Double Horizontal Swivel Socket Member This fitting can be used for attaching flat panels to tubular structures. Specially designed for retail shelving applications, the MH51 can be used as part of a CH51 combination fitting. Ø indicates the diameter of the fixing hole. A T y PE Tube ref. mm Kg A D E F G H Ø MH51-6 6 43 38 11 46 38 10 0.44 D E G H F M 52 T y PE Tube ref. mm Kg A D E F Ø M52-5 5 40 38 19 10 0.37 M52-6 6 43 38 19 10 0.39 M52-7 7 50 45 19 10 0.45 M52-8 8 54 47 19 10 0.46 Male Corner Swivel Socket Member One part of a Type C52 combination fitting. This can also be used for attaching flat panels to tubular structures. Ø indicates the diameter of the fixing hole. A E D F BC 53 T y PE Tube ref. mm Kg A B C D E F BC53-8 8 83 45 1.14 Swivel e lbow Type BC53-8 fitting has been designed as a variable angle in-line connection, adjustable through 202°. A A 202 ° E D WARNING!: An entire structure should not be constructed from Type BC53-8 or any other swivel fitting, as these would not pro - vide sufficient stability or rigidity in the structure due to the free rotation of the fitting. C 53 a djustable t hree Way Swivel Socket Complete combination fitting. Type C53 is made by combining two Type M53 and two Type F50 fittings. For dimensions refer to Type F50 and type M53. See 'Swivel Fittings' on page 11 for more information. Ø indicates the diameter of the fixing whole. T y PE Tube ref. mm Kg A B C Ø C53-888 8 8 8 10.5 1.54 A B C

24. Safety Components Catalogue 24 Copyright © Kee Safety Ltd. All Rights Reserved. L 10 T y PE Tube ref. mm Kg A D E F L10-6 6 52 42 56 0.13 L10-7 7 65 53 64 0.20 L10-8 8 74 60 70 0.30 L10-9 9 90 74 82 0.48 Single Socket t ee Designed to give a 90° butt joint between two tubes. Frequently used for the joint between end uprights and the middle rail where the railing site is straight and level. Also used for base ties on racking. This fitting cannot be used where the tube passing through the sleeve is required to be joined within the fitting. A A F D E L 14 T y PE Tube ref. mm Kg A D E F L14-6 6 50 100 42 0.18 L14-7 7 59 130 53 0.38 L14-8 8 65 148 60 0.34 Straight Coupling Designed to give an in-line joint between tubes of the same size. Frequently used to enable full tube lengths to be used in railing applications. Note: It is not advisable to join the upper and lower rails of a railing within the same bay. A A F D E L 15 T y PE Tube ref. mm Kg A D E F L15-6 6 52 42 56 0.14 L15-7 7 65 53 59 0.28 L15-8 8 74 60 65 0.40 L15-9 9 90 74 78 0.66 90° e lbow A 90° elbow joint, most frequently used as an end joint for the top rail of safety railing on a level site. A A F D E 60 ° –200 ° L 19 T y PE Tube ref. mm Kg A D E L19-6 6 42 75 0.36 L19-7 7 53 90 0.58 L19-8 8 60 90 0.66 a djustable Side Outlet t ee Used to form variable angle joints between 60° and 200°. Not designed to absorb bending loads at barrier intersection. Note: Type L19 fittings are bagged in pairs and are weighed, priced, and sold as such. A A D E A L 20 T y PE Tube ref. mm Kg A D E F L20-6 6 52 42 50 0.19 L20-7 7 65 53 59 0.35 L20-8 8 74 60 65 0.50 Side Outlet e lbow A 90° corner joint most frequently used for the top rail of safety railing. It can also be used for the corner joint of benches, work tables and other rectangular structures. A A F D E A L 21 T y PE Tube ref. mm Kg A D E F L21-6 6 52 42 56 0.16 L21-7 7 65 53 64 0.30 L21-8 8 74 60 70 0.43 90° Side Outlet t ee Most frequently paired with type L20 to give a 90° corner joint for the middle rail of safety railing and other rectangular structures. The upright passes through the fitting. A A F D E A

12. Safety Components Catalogue 12 Copyright © Kee Safety Ltd. All Rights Reserved. P 50 Modified M50-8 with Offset Slot Designed for the securing of various types of panels and flooring to tube structures (i.e. plywood, plastic sheeting, wood planking, etc.). This fitting has one offset flange to allow the flush attachment of panels to tube. Often used with Type P51. See also Type P57. A T y PE Tube ref. mm Kg A D E F G H J K L P50-8 8 61 80 47 32 8 10 11 13 0.48 G F D E J K L H C 51 Double Swivel Socket Complete combination fitting. Type C51 is made by combining two Type F50 fittings and one Type M51. For dimensions refer to Type F50 and Type M51. See ‘Swivel Fittings’ on page 11 for more information. B T y PE Tube ref. Kg A B C C51-555 5 5 5 0.99 C51-666 6 6 6 1.11 C51-777 7 7 7 1.35 C51-888 8 8 8 1.57 C51-999 9 9 9 2.06 C A 85 ° 85 ° M 50 Male Single Swivel Socket Member One part of combination fitting C50. This can also be used for attaching flat panels to tubular structures. Ø indicates the diameter of the fixing hole. Note: Type M50-4 will only mate with a Type F50-4. A E T y PE Tube ref. mm Kg A D E F Ø M50-4 4 28 20 11 6.5 0.06 M50-5 5 40 38 19 10 0.24 M50-6 6 43 38 19 10 0.27 M50-7 7 48 38 19 10 0.36 M50-8 8 54 47 19 10 0.36 M50-9 9 62 45 19 10 0.54 D F MH 50 T y PE Tube ref. mm Kg A D E F G H Ø MH50-6 6 43 38 38 11 46 10 0.30 Male Single Horizontal Swivel Socket Member This fitting can be used for attaching flat panels to tubular structures. Specially designed for retail shelving applications. Can also be used as part of a Type CH50 combination fitting. Ø indicates the diameter of the fixing hole. A F D H E G M 51 Male Double Swivel Socket Member One part of a Type C51 combination fitting. This fitting can also be used for attaching flat panels to tubular structures. Ø indicates the diameter of the fixing hole. A T y PE Tube ref. mm Kg A D E F Ø M51-5 5 40 38 19 10 0.33 M51-6 6 43 38 19 10 0.38 M51-7 7 48 45 19 10 0.46 M51-8 8 54 45 19 10 0.48 M51-9 9 62 52 19 10 0.71 D D E F F 50 T y PE Tube ref. mm Kg A D E F Ø F50-4 4 38 14 11 6.5 0.07 F50-5 5 60 25 19 10 0.28 F50-6 6 60 21 19 10 0.34 F50-7 7 68 21 19 10 0.42 F50-8 8 76 25 19 10 0.52 F50-9 9 83 21 19 10 0.65 f emale Single Swivel Socket Member One part of combination fitting C50. The Type F50 in size 4 has only one ear, while Type F50 in sizes 5 to 9 has two ears. Ø indicates the diameter of the fixing hole. Note: Type F50-4 will only mate with a Type M50-4. A F E D

19. www.keesafety.com 19 Copyright © Kee Safety Ltd. All Rights Reserved. t he Slope Range (86–89) The slope range of fittings consists of fitting Types 86, 87, 88, 89. These fittings are designed to facilitate in-line railings with vertical posts on slopes with angles between 0° and 11°. They can be used to construct railings on access ramps for people with disabilities when used in conjunction with the K ee LI te Type L160 fitting. T y PE Tube ref. Kg A 84-5 5 0.05 84-6 6 0.10 84-7 7 0.12 84-8 8 0.17 84-9 9 0.29 84 Malleable Plug A metal drive-in plug which is difficult to remove when installed. For an alternative in plastic, see Type 77. Note: This fitting can only be used with EN 10255 (ISO 65) medium weight tubing. 86 T y PE Tube ref. mm Kg A D 86-7 7 60 0.55 86-8 8 68 0.76 a ngle t ee Used to join the middle rail to an upright on a guardrail on a slope from 0° to 11°. Tube cannot be joined within this fitting. A A D 11 ° 11 ° 87 T y PE Tube ref. mm Kg A D 87-7 7 60 0.80 87-8 8 68 0.90 a ngle e lbow Used to join the top rail to an end upright on a guardrail on a slope from 0° to 11°. Tube cannot be joined within this fitting. D A A 79 ° –101 ° 88 T y PE Tube ref. mm Kg A D E 88-7 7 60 144 1.02 88-8 8 68 158 1.24 t hree Socket a ngle t ee Used to join the top rail to an intermediate upright on a guardrail on a slope from 0° to 11°. As there are two socket set screws in the sleeve, this fitting can be used to join two ends of rail. A A A D 11 ° E 11 ° 83 Pin f itting This fitting is used in conjunction with Type 78 for gate hinges. T y PE Tube ref. mm Kg A D E F Ø 83-5 5 30 26 38 13 0.20 83-6 6 33 25 38 13 0.25 83-7 7 38 25 38 13 0.29 83-8 8 41 26 38 13 0.30 D F E Ø A 89 T y PE Tube ref. mm Kg A B D 89-7 7 7 144 0.90 89-8 8 8 158 0.93 89-87 8 7 155 0.76 t wo Socket a ngle Cross Used to join the middle rail to an intermediate upright on a guardrail on a slope from 0° to 11°. The upright passes through the fitting. B 11 ° D 11 ° B A

9. www.keesafety.com 9 Copyright © Kee Safety Ltd. All Rights Reserved. A A A 21 T y PE Tube ref. mm Kg A D 21-4 4 34 0.14 21-5 5 41 0.28 21-6 6 46 0.41 21-7 7 60 0.69 21-8 8 68 0.85 21-9 9 85 1.36 90° Side Outlet t ee Most frequently paired with Type 20 to give a 90° corner joint for the middle rail of safety railing and other rectangular structures. The upright passes through the fitting. D A D A A 25 T y PE Tube ref. mm Kg A D E 25-4 4 34 67 0.18 25-5 5 41 82 0.37 25-6 6 46 92 0.49 25-7 7 60 120 0.85 25-8 8 68 136 1.09 25-9 9 84 168 1.74 t hree Socket t ee Most commonly used as the 90° joint between the top rail and an intermediate upright on safety railing. As there are two socket set screws in the sleeve, this fitting can be used where a join is required in the horizontal tube. The Type 10 fitting can be used as an alternative when a join in the tube is not required. E D A A A A 26 t wo Socket Cross Usually paired with Type 25 to give a 90° joint between the middle rail and an intermediate upright on safety railing. The upright passes through the fitting. T y PE Tube ref. mm Kg A B D 26-4 4 4 68 0.13 26-5 5 5 81 0.27 26-6 6 6 92 0.40 26-7 7 7 120 0.65 26-8 8 8 136 0.85 26-87 8 7 126 0.63 26-9 9 9 172 1.46 B B D 27 T y PE Tube ref. mm Kg A D 27-6 6 159 0.82 27-7 7 190 1.24 27-8 8 216 1.49 t hree Socket Custom t ee Used for safety railing on slopes between 0° and 45°, between the top rail and an intermediate upright which is required to remain vertical. Components are held in stock as blanks and then machined to individual requirements. D 0 ° –45 ° A 21 /A 26 T y PE Tube ref. mm Kg A D E A21/A26-8 8 88 60 1.17 Split t wo Socket Cross/90° Side Outlet t ee This fitting performs the same function as either Type 21 or Type 26, but because of its unique hinge and pin system, it can be added to an existing tubular assembly. Type A21/ A26 fittings are supplied and priced as a kit including two casting and two taper pins, which can be assembled in either configuration. D D E A A A 28 t wo Socket Custom Cross Used for safety railing on slopes between 0° and 45°, between the mid-rail and an intermediate upright which is required to remain vertical. These fittings are held in stock as blanks which are machined to individual requirements. Special order only; please specify required angle. A T y PE Tube ref. mm Weight before machined (Kg) A D 28-6 6 159 0.82 28-7 7 190 1.24 28-8 8 216 1.49 Note: When used in pairs, tee will not be handed. The set screws on one side will face inward on the stair or ramp. For an alternative to this fitting, see Type 30. A A D 0 ° –45 ° Note: When used in pairs, tee will not be handed. The set screws on one side will face inward on the stair or ramp. For a 30° and 60° alternative to this fitting, see Type 29. Weights given in the table are for blank fittings.

31. www.keesafety.com 31 Copyright © Kee Safety Ltd. All Rights Reserved. e ngineering The modular Kee aCC e SS components are designed to suit BS EN 10255 (ISO 65) steel tubes. Components are made of galvanised cast iron to BS EN ISO 1461 for long-term maintenance; they are also available with polyester coating in any RAL colour. Any K ee a CC e SS Railing System can be easily installed with a hex tool and tube cutters, and is therefore easily assembled without specialised workers or equipment, saving you both time and money. Kee Safety has a solution for every environment and situation. Kee K L a MP components can be implemented alongside Kee aCC e SS components to create a complete line of complementary galvanised components. Send us your drawings, sketches or layout for a complete detailed proposal. The K ee a CC e SS range of tubular fittings is designed specifically to meet the requirements of the Disability Discrimination Act (DDA), the Building Regulations Part M and British Standard BS 8300. The K ee a CC e SS components provide a cost-effective solution for handrail installations on both new and refurbishment projects. Kee aCC e SS components have been designed to give a smooth handrail with size 7 tube (outside diameter 42.2mm). All fittings can be powder coated in a choice of RAL colours to meet the visibility and ‘not cold to the touch’ requirements of the DDA. K ee a CC e SS is ideal for creating new barriers, but the system can also be used as a retrofit solution, due to its add-on components which allow a new handrail to be added on to existing railing systems. Coupling 514-7 ........... Internal e lbows 515-7 .......... 90° Split 520-7 .......... 90° Solid 554-7 .......... Variable Angle 565-7 .......... w all Mounted End Return 567-7 .......... End Post h andrail Retur Handrail Wall Bracket 518-7 .......... g alvanised Inset 561-7 .......... w all 565-7 .......... w all Mounted End Return 570-7 .......... g alvanised Mounted t ees/Sockets A10-748 ...... Add-on Single h andrail (32mm) 10-840C ...... Single h andrail Capped 10-848 ........ Single h andrail A10-848 ..... Add-on Split Single Handrail (38mm) 26-840 ........ Twin h andrail 26-840C ..... Twin h andrail Capped 555-8 .......... Top Fix Rail Assembly a luminium Joints 410-8 ........... Upright connector 418-40 ........ h andrail Bracket Miscellaneous 84-848 ........ Upright Top Cap 508-7 .......... g ap w asher f it ti ngs by f unction DD a Components Kee aCC e SS Basic a ssembly h ow these components work together to give you the most durable and flexible DDA-compliant railing system available. Handrail - size 7 Upright - size 8 26-840C 518-7 Ø 4.8mm RIV et S 554 -7 DOUBL e OR SINGL e O ff S et D e SIGN 520-7 SIZ e '7' (Ø 42.4) R a IL 515 - 7 INCLUD e S 1 X SOCK et S H ea D SCR e WS 2 X S et SCR e W 518-7 S et SCR e WS Ø 4.8 RIV et S 1.2M 10-840C 514 -7 567-7 80mm SIZ e '8' (Ø 48.3) UPRIGH t 10-848 C a N B e f INISH e D IN a L te RN at IV e e NDINGS

25. www.keesafety.com 25 Copyright © Kee Safety Ltd. All Rights Reserved. L 25 t hree Socket t ee Commonly used as the 90° joint between the top rail and an intermediate upright on safety railing. As there are two socket set screws in the sleeve, this fitting can be used where a join is required in the horizontal tube. The Type L10 fitting can be used as an alternative when a join in the tube is not required. A A A T y PE Tube ref. mm Kg A D E F G L25-6 6 52 42 50 104 0.21 L25-7 7 65 53 59 130 0.35 L25-8 8 74 60 65 148 0.51 L25-9 9 90 74 78 180 0.82 E G D F L 26 t wo Socket Cross Usually paired with Type L25 to give a 90° joint between the middle rail and an intermediate upright on safety railing. The upright passes through the fitting. A A A F E D T y PE Tube ref. mm Kg A D E F L26-6 6 42 56 104 0.17 L26-7 7 53 64 130 0.28 L26-8 8 60 70 148 0.45 L26-9 9 74 82 180 0.66 L 29 30°–60° Single Socket t ee This adjustable fitting is most frequently used for struts and braces. It can be used at any selected angle between 30° and 60°. Suitable for connecting an angled staircase rail to a vertical upright. A A T y PE Tube ref. mm Kg A D E F G L29-7 7 82 95 27 53 0.32 L29-8 8 93 108 30 59 0.41 G D E F 30 ° –60 ° L 30 30°–45° a djustable Cross This adjustable fitting can be used for railing on staircases between the mid-rail and intermediate upright which is required to remain vertical. It can be used at any selected angle between 30° and 45°. A A A E D F T y PE Tube ref. mm Kg A D E F L30-7 7 215 53 54 0.52 L30-8 8 245 59 60 0.69 30 ° –45 ° L 35 t hree Socket Cross Most frequently used to tie uprights with horizontal tube in three directions, all 90° to the upright. The upright passes through the fitting. A A A G F D E T y PE Tube ref. mm Kg A D E F G L35-6 6 43 56 104 52 0.31 L 45 Crossover Designed to give a 90° offset crossover joint. Frequently used on safety railing utilising a continuous horizontal rail, minimising tube cuts to reduce costs. Type L45 may also be used to allow intermediate levels on racks. Note: Tube cannot be joined with this fitting. A A E D T y PE Tube ref. mm Kg A B C D E L45-6 6 44 40 0.12 L45-7 7 54 50 0.31 L45-8 8 61 56 0.35

17. www.keesafety.com 17 Copyright © Kee Safety Ltd. All Rights Reserved. 69 Railing f lange with t oeboard a daptor Designed for guardrail and balus - trade applications with the added benefit of attaching a toeboard to the base. The base plate holes are suf - ficient diameter to allow for attachment with either a mechanical or chemical anchor. The side plates have slotted holes to allow for a degree of sideways movement for ease of installation. (See page 36 for Toeboard). Ø indicates the diameter of fixing holes. A T y PE Tube ref. mm A D E F G H J K 69-6 6 130 75 89 95 58 15 10 69-7 7 145 80 90 97 58 20 10 69-8 8 160 90 90 112 58 20 10 Kg L M N P R Ø 100 35 7 45 25 11 1.72 115 40 7 47 25 11 1.90 130 50 7 54 25 11 2.30 N M L P E R D E K J G H 71 T y PE Tube ref. mm Kg A D E F 71-6 6 125 143 25 0.24 71-7 7 150 154 25 0.32 71-8 8 155 167 25 0.36 Weather Cap Designed for roof guardrailing to ensure a weathertight seal for base fixing flanges. The weather cap is secured to the upright by means of a combined sealant adhesive. A separate information sheet detailing fixing instructions is available on request. A E D F 70 Rail Support Designed to carry handrails along walls or to fix structures back to walls. The tube passes through the fitting and cannot be joined with the fitting. Type 70 is also used to attach toeboards to the base of guardrail uprights. h oles provided for countersunk flat head screw fixings only. A T y PE Tube ref. mm Kg A D E F G H Ø 70-5 5 54 76 46 57 38 8 0.36 70-6 6 58 88 40 70 38 8 0.44 70-7 7 64 102 45 82 45 8 0.56 70-8 8 70 108 52 82 58 8 0.78 F D G E WARNING! : Type 70 fittings are not designed to be used as base flanges for full height guardrails or handrails. 75 T y PE Tube ref. mm Kg A D 75-4 4 22 0.05 75-5 5 25 0.13 75-6 6 26 0.13 75-7 7 25 0.15 75-8 8 25 0.19 Collar Commonly used to support another fitting if the latter is required to be left untightened, such as gate hinges. Type 75 is also useful when the loading on a structure exceeds the maximum permitted slip load for a socket set screw, as it provides additional support. A D 72 Stair t read Support Suitable for most types of stair tread, including timber, open steel and checker plate. Fixing of the tread is by two bolt holes in each fitting. (Special order only.) Ø indicates the diameter of fixing holes. WARNING!: If Type 72 fittings are to be used for a permanent application or subjected to high loads, the stair tread support tube which is located at its ends with a single set screw, should be drilled and pinned to avoid rotational slip. A T y PE Tube ref. mm Kg A D E F G H J # 72-8 8 203 39 51 153 20 33 12 1.25 G F D E H J