Dokumentation

Ose_directory e-shot

2652 Visninger •Checkline II maintenance manual

3020 Visninger •Chemsplash Pro WD40 Test

2377 Visninger •Ergonomi 2006

2922 Visninger •Ose_directory Suspension harness

2688 Visninger •Procurement Guide annonce Health and Safety International - Europe's magazine for employee protection and personal protective equipment

3387 Visninger •Demonstration af velcro strop til montering/påsætning af gasdetektor på faldsikringssele

3156 Visninger •VISOR Installation steps

3947 Visninger •Desinfektionsprodukter med effekt på Coronavirus 2019-nCoV

2938 Visninger •Hearing protection 3M

2491 Visninger •Statistik for arbejdsmiljø 2014

2947 Visninger •LOTO_GuideBook_Europe_English

2496 Visninger •Remote area lighting system

2262 Visninger •Isol8 - The Ultimate Absorbent for Spills

2274 Visninger •Magazine Arbejdsmiljø - november 2012

2438 Visninger •KEE_DOME_MINI

2347 Visninger •TDS Speedglas 9100

2530 Visninger •The Pocketbook of Lean Visuals

2525 Visninger •Instructional video Sign holder

1822 Visninger •PREMARK installation manual

2489 Visninger •D-S CSR Håndbog

16822 Visninger •Find handskestørrelse - størrelsesguide for handsker

9885 Visninger •3M jupiter manual

6045 Visninger •9100 Manual

4930 Visninger •EN 388 nye mærkninger forklaring

4683 Visninger •D-S 70 års om os brochure

4645 Visninger •Forklaring af den nye EN ISO 374 kemikalier norm

4580 Visninger •Faldsikring flyer

4129 Visninger •Hvordan du kalibrere en 3M Jupiter luftstrøms enhed

3974 Visninger •VISOR Installation steps

3947 Visninger •Guide til valg af åndedrætsværn

3492 Visninger •TR-300 Bruger manual

3476 Visninger •VARMEX 2000 Fordele

3435 Visninger •Procurement Guide annonce Health and Safety International - Europe's magazine for employee protection and personal protective equipment

3387 Visninger •3M TR 300 PAPR training video

3337 Visninger •Demonstration af velcro strop til montering/påsætning af gasdetektor på faldsikringssele

3156 Visninger •Procedure for iklædning af engangsbeklædning

3133 Visninger •3020 Solcreme SPF 30 datablad

3118 Visninger •3M 8825+ 8835+ 06936+ 1895V+ BSI CE-Cert_(CE_705688_(Iss_30_09_2019))

3106 Visninger •Aura_Gen_3_BSI_Cert_(CE_681745_(Iss_07_10_2019)

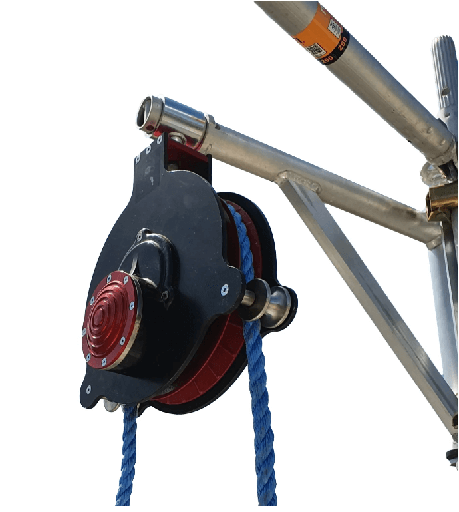

3068 Visninger •BIGBEN® løftetalje med kontrollerbar sikkerhedsbremse - LH-7135

| Visninger | |

|---|---|

| 670 | Totale visninger |

| 0 | Medlemmer visninger |

| 670 | Offentlige visninger |

Del via email

Venligst login for at dele dette document via email.

Indlejr på din hjemmeside

15. bigben safety.com NOTES

1. SCAFFOLD BRAKE PULLEY USER GUIDE/ INSTRUCTION MANUAL LH-7135

16. bigben safety.com Manufactured by: SWISSLOGO AG CH 8172 Zurich, Switzerland Tel +41(0)43 411 1100 The Marque of Excellence SCAFFOLD BRAKE PULLEY

12. bigben safety.com STORAGE All devices should be stored in the following manner:- • Stored in a central protected location allowing assurance of inspection issues and returns. • Kept in a cool dry place, away from direct sunlight preventing degradation of fibres from Ultraviolet radiation. • Protected from damage by chemical attack, sharp objects, heat and cold. • Should be stored with record card and operation manual at all times. • When finished return device to store, NEVER leave device lying around on site.

14. bigben safety.com INSTRUCTIONS USING THE CORRECTLY Securely attach device to scaffold pipe. Attach the load. Lift load to required height. LOAD (MAX 50 KG LOAD (MAX 50 KG

10. bigben safety.com INSPECTION AND MAINTENANCE MAINTENANCE: (No special training is required) This product requires minimal ongoing maintenance apart from visual checks and general housekeeping, cleaning and the occasional simple replacement of the brake cartridge. Hand wash using hot water and mild detergent (NO chemicals) then rinse with clean water allow drying naturally with rope exposed. The only wearing part is the brake shoes which cannot catastrophically fail and are proven for minimum 100,000m use under 25kg load. (Excessive wear would simply result in an increasing descent speed, which can be noticed and rectified before it becomes an issue). The Brake shoes should be changed annually or sooner if excessive use requires. The brake shoes are assembled on a cartridge which can be simply changed in only 2 - 3 minutes, by any able person using a standard hex drive for removing 8 screws.

11. bigben safety.com CHANGING THE BRAKE CARTRIDGE Simply undo the 8 screws on the front cover of the brake drum, withdraw the brake cartridge, check the inside of the drum is free from any contaminants and simply plug a new cartridge. ( it will automatically align to the correct position ). The Cartridge is readily available either on a replacement or exchange basis from approved dealers and being compact and lightweight it can be mailed to any site location globally. Annual Inspection and service by an approved service centre is also recommended. If any part of the product is found to be defective, please complete below section stating all defects and remove from service immediately. Comments: Date: DD MM YYYY Inspector:

5. bigben safety.com INSTRUCTIONS FOR USE The Brake Pulley has been designed and manufactured to be used at height. It implements a breaking mechanism which ensures that if the load is released under any circumstance it descends to the ground, but in a controlled manner. Descent speed can be pre-determined by gearing, brake liner, brake shoe or combination thereof. GENERAL USE: • Do not install or use this brake pulley in a different way from what this manual specifies. Manufacturer is not responsible for any damage due to poor use or neglecting the safety measures. • The work area must respond to the safety requirements by law. In particular it is forbidden for persons to operate below the suspended loads. • Do not use brake pulley for lifting loads or heights exceeding the values specified in the product specification. • Do not use ropes with diameters different from ones stated in specification. • Do not use ropes with the diameter reduced by wear below the minimum diameter stated, or if strands are deformed or damaged. The malfunctioning of the pulley due to use with a damaged rope is the responsibility of the user. • Before use, check the correct positioning of the pulley on the scaffold and test the braking efficiency related to the working height and rope weight. • When using the brake pulley personal protective equipment must be used. Safety gloves additionally should be used. • Store product in a dry and clean environment after use, if any dirt or dust present it must be cleaned, preferably by compressed air. • This device must only be serviced by a trained and competent individual. Never attempt to service this unit or tamper with its function in anyway. • Do not remove, or substitute any spare parts of the pulley with non-original parts

7. bigben safety.com OPERATION BEFORE USE: • Inspect work area ensuring it is free from any obstructions that may prevent the safe use of the device. • Safety equipment must always be used when operating this product e.g safety boots, gloves and hard hat. • Two competent operators must always be present, one on the ground and one at the working level. • Ensure the rope it is inserted in the correct direction as seen figure 1 Figure 1- Direction of rope inserted into braked pulley WARNING - BEFORE USING THE BRAKED PULLEY IT IS COMPULSORY TO:- • Check the brake efficiency, does pawl engage when load is dropped and speed is exceeded. • Check the free rotation of the swivel attachment onto the pipe • Check the free rotation of the rope pulleys. • Check to ensure all fixings are secure and have not been damaged or tampered with. • Check the condition of rope- any signs of damage from heat, sharp objects, and chemicals. If in doubt replace the rope. NOTE - If the braked pulley does not pass with any of these points then it should be placed in quarantine for service by a trained and competent person. MAX 50KG

8. bigben safety.com OPERATION FITTING THE BRAKE PULLEY • Carry out pre-use inspection of the environment before attaching device. • The attachment point must be a standard pipe for scaffolds, with external diameter 48 mm. • The attachment of the pulley is fixed at the extremity of the pipe and locked against the longitudinal movements by two clamps, one per side of the brake pulley. USING THE PRODUCT: Lifting the Load • After the routine checks firmly secure the load and start pulling the rope lifting the load to the desired level. • • During this process if the rope is suddenly released, the load starts a small descent and immediately afterwards the brake is automatically engaged and load descends to the ground in a controlled manner. • • This controlled descent speed allows the user to re- gain control of the load safely, and can be done using one hand. • • Always lift a load which is adequate to the physical capacity of the operator, also related to the lifting height. • • To ensure maximum safety of the operator at ground when lifting loads, they must stand as far as possible from the load descent area. Lowering the Load The same outcome applies when the load is lowered from the work height. If the rope is released when lowered the brake also activates descending the load in a controlled manner.

3. bigben safety.com GENERAL INFORMATION PART IDENTIFICATION DESCRIPTION The Big Ben Braked Pulley is supplied as controlled descending unit. The load is held on a drum that is attached to a ratchet and a gear ring. If released the pawl engages activating the breaking mechanism within the device which lowers the load in a controlled manner. WARNING Incorrect use of this device could be fatal, so prior to use you MUST: • Only be used by persons in a fit medical condition that can work fr om height and do so in both normal and an emergency situation. • Read and thoroughly understand the operating manual before inspection or use of this product. • If there are any points in this operating manual that you are unsure of, seek advice from a trained individual. • Be fully trained with operating the device and familiar with the correct actions in case of and emergency. • Be familiar with the use of the product prior to working from height. • Carry out appropriate pre use checks and quality assurance. • Assess the work area to ensure adequate supporting structural attachments are in place. • Understand and accept the risk involved in use of this product FAILURE TO COMPLY WITH ANY OF THESE FACTORS MAY RESULT IN SERIOUS INJURY OR DEATH. CONFORMITY: The product is CE marked and issued with a Certificate of Conformity in compliance with BHSR of the EC PPE Directive (89/686/EEC) where no EN standard can be directly applied. The certificate also contains details of final inspection carried out together with dynamic testing. The Supply of machinery (safety) regulations 2011 and Loler have also been considered, in the provision of the certificate of conformity. EN. No applicable EN standard can be referenced for this equipment.

2. bigben safety.com IMPORTANT INFORMATION Always Read Instructions Before Use This user manual must be thoroughly understood and available to users at all times. The manual contains information on Safe Use, Product Inspection and Maintenance. Serial Number: Date of Manufacture: DD MM YYYY The annual service should be carried out NO LATER THAN 12 MONTHS AFTER COMMISSION. If defective complete the section below remove from service and quarantine immediately: Defects: Date: DD MM YYYY Signature:

9. bigben safety.com INSPECTION AND MAINTENANCE INSPECTION VISUAL INSPECTION SHOULD BE CARRIED OUT REGULARILY This device and all equipment must be visually inspected by a competent individual when delivered to site also thoroughly inspected before and after every use. ROPE - Examine for cuts, cracks, tears, abrasion* and scorch marks, burns or chemical attack. DRUM / RATCHET - Pull on rope sharply to determine if pawl engages to activate brake mechanism. METAL WARE – Inspect for signs of damage, distortion or corrosion as well as ensuring correct operation. LABELLING - Check that all information included is legible. * Common abrasion wear within rope may be caused by passage over sharp edges when under tension which may result in serious loss of strength. Slight damage to the outer fibres could be considered harmless; however serious damage such as reduction of diameter should lead to rejection and be immediately removed from service. ROUTINE INSPECTIONS It is recommended that, in addition to the above, the unit is subjected to a thorough routine inspection at least every 6 months. A record card is contained with this manual and should be filled after each routine inspection. • Thorough inspection is to be given to each of the following: • Check the unit is clear of any debris and the rope is running freely • Check the rope is in good condition, clean and free of contaminants. • Damaged or contaminated rope should be discarded • Check the pulley is rotating freely smoothly in both directions • Check that speed of descent is acceptable. (e.g. 25kg load approximately 1.5m / sec) • (If the lowering speed is too fast change the brake cartridge) • Check the brake linings

13. bigben safety.com BRAKE PULLEY EXAMINATION FORM DEVICE SERIAL NUMBER DATE OF MANUFACTURE D D M M Y Y DATE ISSUED D D M M Y Y EXAMINATION CONDITION DEFECTS POOR GOOD List all salient points bout each part stating all issues present. KARABINERS/SWIVELS Examine for damaged or distorted hooks or faulty springs, Check that all connectors, karabiners and swivels all function correctly. Open and close freely. Swivel that attaches to the scaffold and load rotate freely. MECHANICALS Inspect all parts ensuring no damage. Check that the ratchet pawl engages and activates the brake mechanism when given a sharp pull, then releases when not under tension. ROPE Check entire length of rope for any damage. This may include cuts, burns, cracks, tears. Ensure all rope can be pulled through with no issues. FIXINGS Check entire device for damaged screws or screws that have been tampered with. LABEL Check that label is present and legible. Check date to ensure product is within its life span. ROPE BAG IF APPLICABLE Check for any signs of damage to:- structure, adjustable straps, stitching and waterproof shell/base. TESTED BY: SIGNATURE DATE OF EXAMINATION D D M M Y Y

6. bigben safety.com PART IDENTIFICATION 1 Swivel Attachment Point 2 Anchor Plate 3 Front/Back Plate 4 Module 5 Module Cap 6 Ratchet And Gear Assembly 7 Rope Pulley 8 Drum 9 Brake Mechanism 10 Protective Shroud 11 Device Labels 1 2 3 4 5 6 7 8 3 9 10 11

4. bigben safety.com GENERAL INFORMATION PRODUCT SPECIFICATION PRODUCT WEIGHT: 7KG WITHOUT ROPE MAXIMUM WORKING LOAD: 50KG MAXIMUM SUGGESTED WORKING HEIGHT: 100M MAXIMUM WORKING HEIGHT: N/A ROPE DIAMETERS TO BE USED: 16-18MM DOUBLE BRAIDED / 18MM POLYPROPYLENE (3 STRAND) SUPPORTING ON STANDARD SCAFFOLDING PIPE EXTERNAL DIAMETER: 48MM MAXIMUM ROPE LENGTH: 200M PRODUCT LABELS SWL-50KG REFER TO THE MANUAL SUPPLIED WITH THIS PRODUCT FOR DETAILED OPERATING AND MAINTENANCE INSTRUCTION REF: 7135 SN-00001234 DOM - 02/17 1 Brand Marking 2 Product Number 3 Serial Number 4 Date of Manufacture 5 Maximum Safe Working Load 6 Read User Manual 7 CE Mark 8 Brand Marking 1 2 3 4 5 6 7 8

Relaterede produkter

To install this Web App in your iPhone/iPad press ![]() and then Add to Home Screen.

and then Add to Home Screen.